Our twin-screw extruder is a high-speed, co-rotating extruder ideal for your compounding needs. Our durable extruders offer reliability in the most demanding jobs such as the extrusion of plastics with high percentages of fillers, reinforcing fibers, or with heat sensitive or shear sensitive additives (such as flame retardants, glass fibers, etc.). You will find our twin-screw extruders to be extremely useful in the production of rigid PVC and wood fiber blends.

WORKING PRINCIPLE

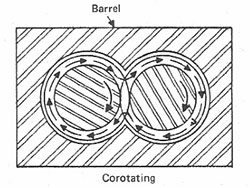

All extruders from ASG Recycling comes standard with our patented Heat Wave Stabilization™ where heat is evenly dispersed throughout the entire length of the barrel. This even distribution of heat, combined with co-rotating screw shafts that evenly blend the molten plastics into each other (in a figure 8 motion), produces the ideal environment for the plastic pelletizing process. We also manufacture counter-rotation extruders based on our customer’s needs and specifications.

Our extruders also come standard with a hydraulic screen changer to ensure continuous operation during screen changes. Made of high quality blended steel strengthened using gas nitriding technology, the drive shaft and barrel are specially treated to ensure against corrosion and wear.

Taking the best of both worlds, a twin-screw extruder can be coupled with a single-screw extruder and a 2-stage array. In this setup, a larger twin-screw extruder is used primarily for the purpose of mixing and compound dispersion. The molten plastic from this process then travels to a smaller, single-screw extruder, where better material extruding can be achieved.

Depending on your preference on “melt pelleizing” or “strand pelletizing”, a water-ring cutter or pellets granulator with water tank can be added. To further improve automation, a vertical dewatering machine with blower to a product silo can also be implemented. ASG Recycling Machinery is your all in one solution to your pelletizing needs.

TECHNICAL SPECIFICATIONS

| Model #: | Screw Diameter: | L/D: | Driving Motor: | Output: |

| SHJ50/SJ120 | ⌀50.2mm / ⌀120mm | 24/48, 7/20 | 37-45 KW / 30-37 KW | 150-300 KG/H |

| SHJ75/SJ150 | ⌀62.4mm / ⌀150mm | 24/48, 7/20 | 55-75 KW / 37-45 KW | 150-300 KG/H |

| SHJ75/SJ180 | ⌀71mm / ⌀180mm | 24/48, 7/20 | 90-110 KW / 45-55 KW | 300-600 KG/H |

| SHJ95/SJ200 | ⌀93mm / ⌀200mm | 24/48, 7/20 | 132-135 KW / 55-75 KW | 500-1,000 KG/H |

*Larger, more powerful models available based on your request.

ADDITIONAL IMAGES

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.