Our single-shaft plastic shredder machines are extremely robust and powerful machines capable of efficiently shredding a wide range of material including plastic, wood, paper, textile, tires, packaging, biomass, and more. It’s specially designed to shred thick materials that are highly resistant to cutting such as plastic blocks and sheets, buckets and drums, various types of timber, extruded polymer pipes, and more.

You will find many of our heavy-duty plastic shredders being commissioned in tough industries such as in municipal solid waste processing plants, material recovery facilities (MRFs), and recycling facilities dealing with commercial and industrial waste.

WORKING PRINCIPLE

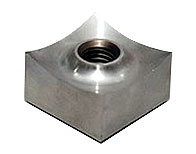

Our single-shaft plastic shredders use unique, square knives that are bolted securely onto a large, closed rotor in a staggered array. As the square rotor knives are mounted with the corners protruding, jagged-teeth knives are mounted within the cutting chamber that act as the stationary knives. Unlike plastic granulator machines that spin at high speeds, single-shaft shredders are relatively quiet, slow cutting machines that spin between 60-100 rotations per minute. As material is fed into the shredder, a hydraulic assisted drawer pushes the material against the rotor where it will be continuously cut until it reaches the desired size as designated by a screen filter that is fitted beneath the cutting chamber. The material will continue to be shredded until it is small enough to fall through this screen filter.

As our single-shaft plastic shredder machines are often placed in front of the most demanding jobs, the frame and structure of our shredders use high-thickness sheets and tubular. The square knives are treatment strengthened and use only the highest quality SKD11 steel (D2 equivalent) to ensure against dulling. Depending the capacity you require, we offer a variety of standard single-shaft shredders for your choosing.

The plastic recycling machines we manufacture are made with usability in mind and our single-shaft plastic shredders are no different. You will find our plastic shredders to offer motorized access to the cutting chamber as well as motor assisted screen changes as standard equipment.

TECHNICAL SPECIFICATIONS

| Model # | Main Motor Power | Hydraulic Motor Power | Rotary Diameter | Rotating Speed | Approx. Capacity |

| DS-600 | 30 KW | 4 KW | ⌀400mm | 85 RPM | 400-600 KG/H |

| DS-800 | 45 KW | 4 KW | ⌀400mm | 85 RPM | 600-800 KG/H |

| DS-1000 | 37 KW x 2 | 5.5 KW | ⌀450mm | 80 RPM | 800-1200 KG/H |

| DS-1200 | 45 KW x 2 | 5.5 KW | ⌀500mm | 70 RPM | 1500-2000 KG/H |

*Larger, more powerful models available based on your request.

SINGLE-SHAFT VS DOUBLE-SHAFT PLASTIC SHREDDERS

There are generally two types of plastic shredder machines being used in plastic recycling today, either single-shaft or double-shaft plastic shredders. While they are both able to handle large-sized, bulky plastics, you will find single-shaft shredders to better handle solid, thick pieces such as plastic purging, runners, pallets, and even wood, branches, and bones.

Double-shaft shredders use shear blades to cut the plastic material and are better suited for handling bulk volumes of hollow, light-weight plastics such as PE films, PP tubes, HDPE drums, and even rubber tires, automotive parts, and electronic waste.

ADDITIONAL VIDEOS & IMAGES

WARRANTY

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.