PROJECT OVERVIEW

We received an interesting inquiry about the recycling of baby car seats from a manufacturer in the USA. After finalizing a custom solution and signing the contract, we started manufacturing the various pieces of recycling machinery. This was the easy part.

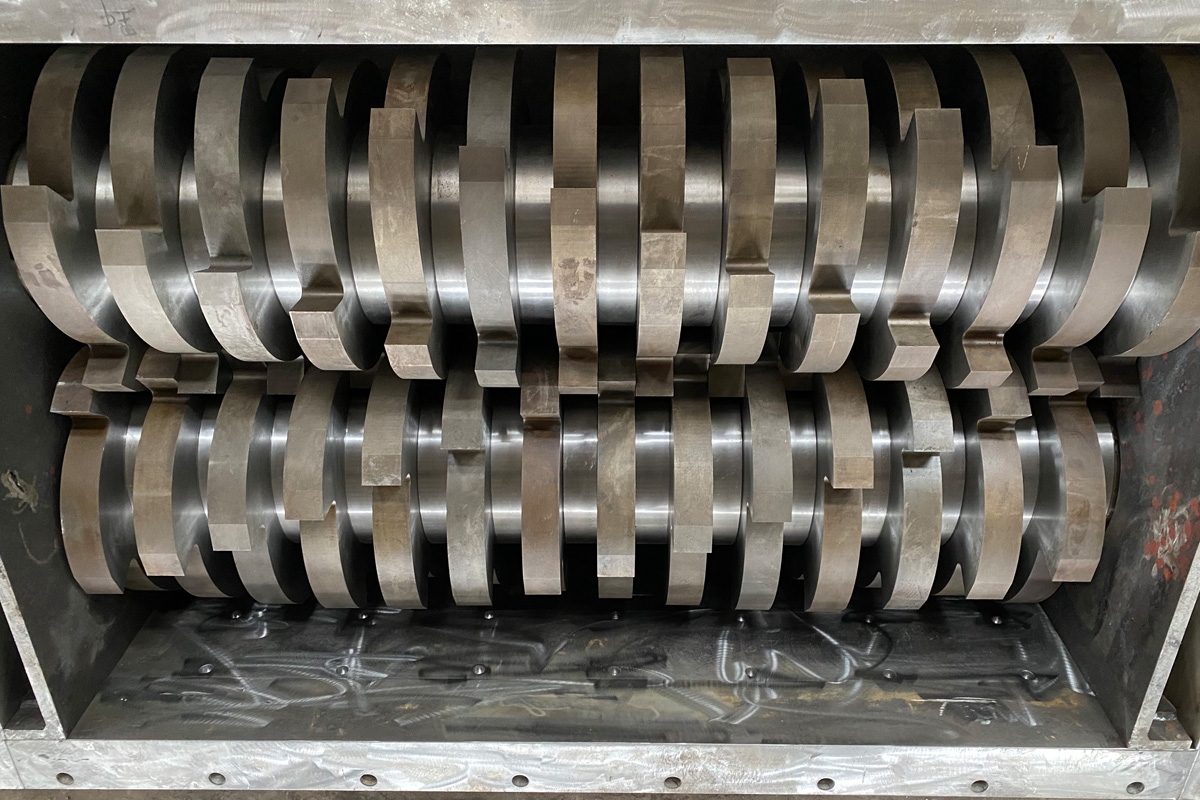

We ran into a road block when optimizing this shredding line and giving our customer a live test before shipment. To set things up properly, we decided to purchase 100 brand new baby seats costing us over $5000 dollars to be thrown into our shredders. This was probably the most expensive live test we had ever conducted for our customers.

The customer was very appreciative of our efforts and treated our staff members to a very nice dinner afterwards. All in all, this was another great example of business turning into long term friendship.

MACHINERY LIST

Rubber Belt Conveyor –> Double-Shaft Shredder –> Belt Conveyor With Suspended Magnetic Separator –> Plastic Granulator –> Discharge Auger

- Project: Baby Seat Shredding Plant

- Year: 2019

- Location: Arkansas, USA

- Purpose: Shred & Granulate Baby Car Seats Into Plastic Regrinds + Remove Metals

- Capacity: 1 ton/hr