Our standard heavy-duty plastic granulator machines, sometimes called plastic crushers, are essential machines in the plastic recycling industry. These specially designed granulators are extremely durable and have the unique ability to quickly and efficiently cut various plastic streams into small uniform flakes or regrinds.

As one of our most sold type of plastic recycling machine, these granulators are packaged in many of our complete recycling solutions including our popular PET bottle washing lines, plastic film recycling lines, and more.

WORKING PRINCIPLE

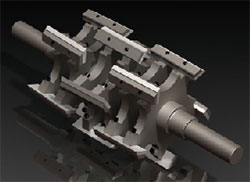

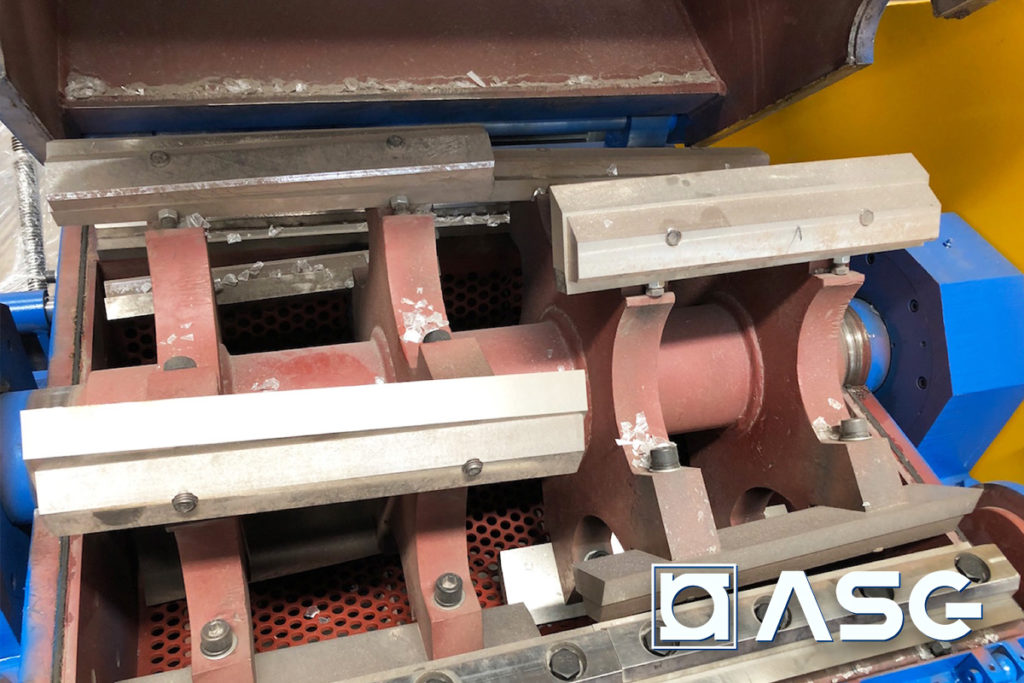

At the core of our plastic granulator machine is an open rotor mounted with heavy-duty knives in either a double-scissor cut or v-shape array based on your requirements. As the rotor is spun at high speeds, the rotor knives come in contact with stationary knives that are mounted within the cutting chamber. The material is continuously cut until they are small enough to pass through a screen filter.

Generally speaking, our filter screens are between 10mm to 100mm but can be customized according to your requirements.

Our standard plastic granulator houses 12 rotor and 3 stationary knives. All knives use only ultra durable D2 (equivalent to SDK11) high-carbon, high-chromium steel which ensures the longest usage times before requiring sharpening. All knives are easily adjustable with hydraulic assisted access to the cutting chamber.

APPLICATIONS

This general purpose plastic granulator can be used in a variety of applications for plastic recycling including but not limited to grinding plastic bottles, films, and a variety of small rigid plastics.

For added convenience, we also offer wet plastic granulator machines that have additional rubber sealing and water inlet hose attached allowing a constant stream of water to be sprayed while the plastic is being cut. This helps clean the plastic scrap while keeping the blades cool during operation.

TECHNICAL SPECIFICATIONS

| Model # | Rotor Diameter | Rotor Width | Rotating Speed | Approx. Output | Motor Power |

| SWHB600 | ⌀450mm | 600mm | 400-600 rpm | 300 kg/h | 37KW |

| SWHB800 | ⌀500mm | 800mm | 400-600 rpm | 600 kg/h | 45KW |

| SWHB1000 | ⌀600mm | 1000mm | 400-600 rpm | 900 kg/h | 75KW |

| SWHB1200 | ⌀700mm | 1200mm | 400-600 rpm | 1200 kg/h | 90KW |

*Larger, more powerful models available based on your request.

PLASTIC GRANULATORS VS SHREDDER MACHINES

Plastic recycling granulators are high-speed machines capable of cutting smaller-sized, thin plastics into flakes and fine regrinds. Due to it’s fast rotation speeds, the operator must be careful not to have hard contaminants such as metals or rocks in the input stream. Metals such as nuts and bolts will easily damage the machine including very easily chipping the cutting blades. To ensure metals are not not present, we suggest adding a magnetic suspension separator above the conveyor system.

Plastic shredder machines while also used in size reduction in plastic recycling are low-speed, more robust machines capable of cutting large pieces of plastic. They are also more forgiving with contaminants. Therefore, plastic shredders are often used to precut large pieces of plastic into smaller sizes suitable for use in plastic granulators. The granulator then further reduces the plastic into flakes or regrinds.

ADDITIONAL IMAGES

WARRANTY

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.