This highly effective cold water washing system is an asset for any plastic recycling plant looking to produce a clean final product stream. As in its name, this machine makes use of the friction between plastic pieces to rub contaminants away.

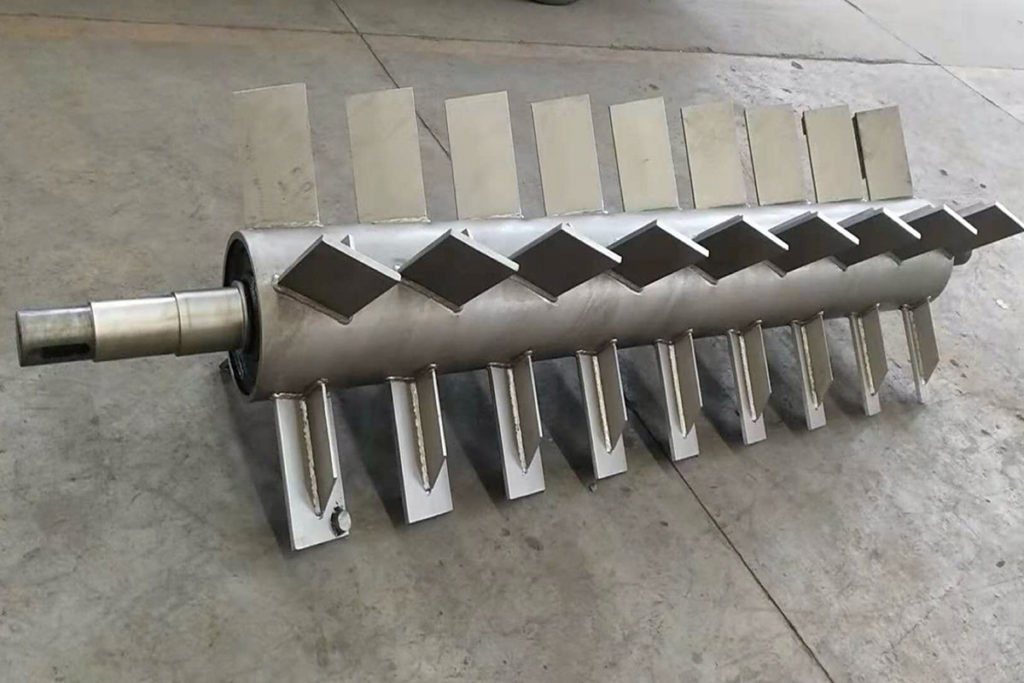

At the core of this recently redeveloped friction washer machine is a long, fast-rotating shaft mounted with many tilted panels / paddles that spins at more than 1,000 rotations per minute.

WORKING PRINCIPLE

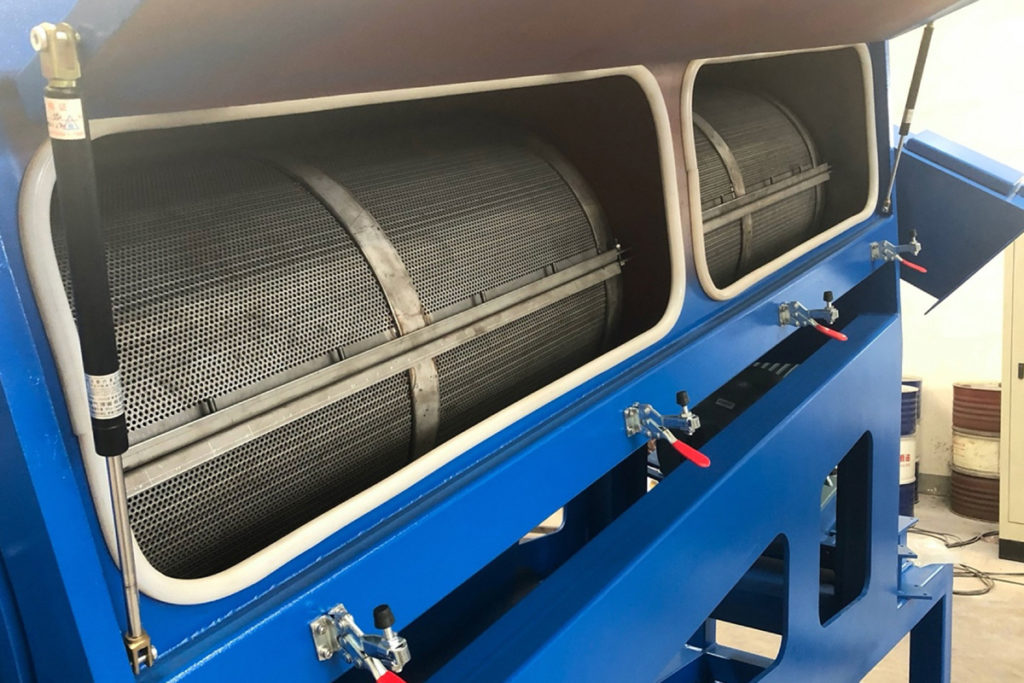

This is an ingenious yet simple machine that forces the plastic flakes, films and regrinds to rub against each other at high speeds. If you take a look inside the rectangular casing, a circular mesh screen surrounds the fast rotating shaft. As the plastic stream enters the cavity, the plastic is continuously spun against the mesh screen. This causes an immense amount of pressure and friction where contaminants such as dirt, paper, cardboard and other debris are effectively loosened and passes through the mesh screen.

Instead of drenching the cavity completely in water, water jets and nozzles are used to conserve water. The entire piece of machinery is set at a strong incline with the dirty plastic stream entering at the lower end. This allows the plastic to stay within the washer longer resulting in cleaner plastics that exit at the top.

TECHNICAL SPECIFICATIONS

| Model #: | Motor Power: | Main Shaft Diameter: | Rotating Speed: | Capacity: |

| HXJ400 | 37KW | 400mm | 1400 RPM | 400 – 800 KG/H |

| HXJ550 | 45KW | 550mm | 1200 RPM | 600 – 1000 KG/H |

| HXJ750 | 55KW | 750mm | 1080 RPM | 1200 – 2000 KG/H |

*Larger, more powerful models available based on your request.

ADDITIONAL IMAGES

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.