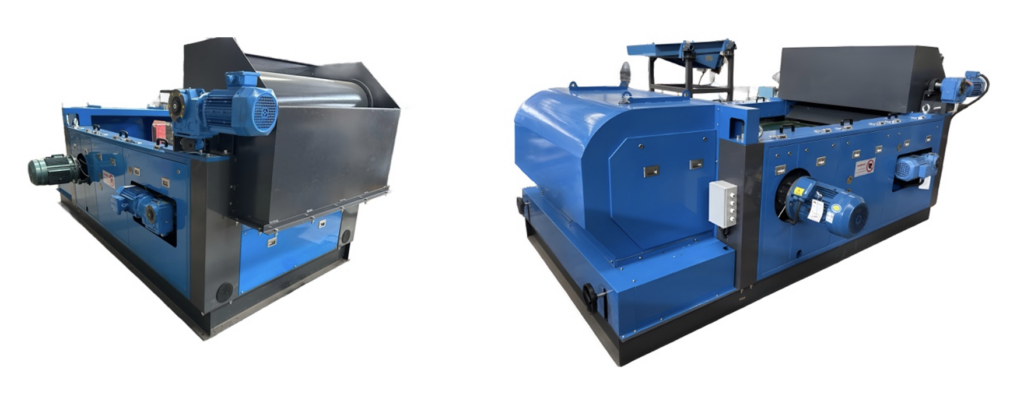

Our eddy current separators are key pieces of machinery for separating aluminum & other non-ferrous metals from a variety of process streams. As non-ferrous metals are generally worth more money, recovering this stream is an essential part of numerous recycling facilities throughout the world.

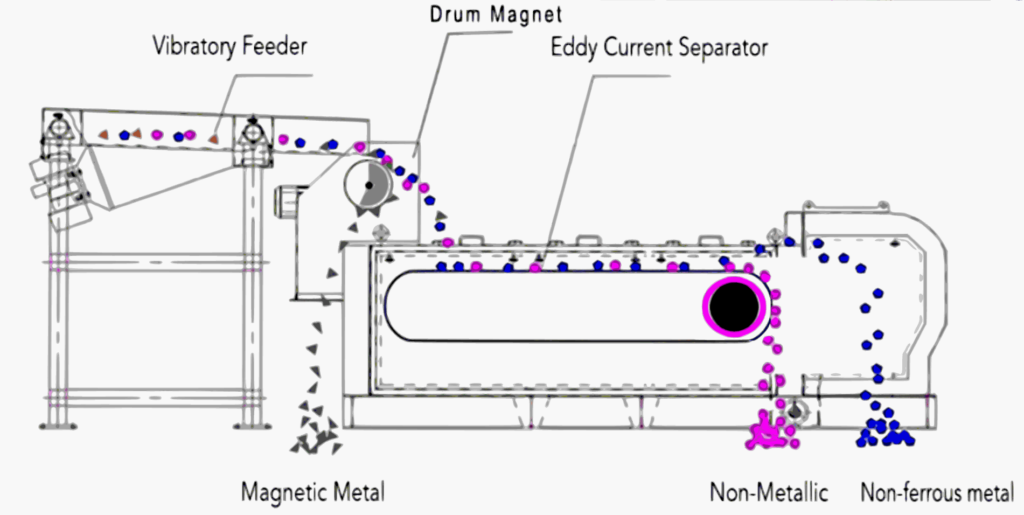

WORKING PRINCIPLE

The basic concept of an eddy current separation is relatively simple. At the core of this equipment is a magnetic (either permanent or electromagnetic) rotor with alternating polarity spinning rapidly within a metallic drum. The alternating magnetic fields created by this process creates “eddy currents” in the non-ferrous metals that pass through. As material stream passes through these eddy currents via a conveyor, the non-ferrous metals are repelled away and collected while other materials fall off the end of the conveyor.

Our eddy current separator is being used in the removal of non-ferrous metals from municipal solid waste, auto shredding operations, glass cullet, electronic waste (WEEE), UBC reclamation, and more.

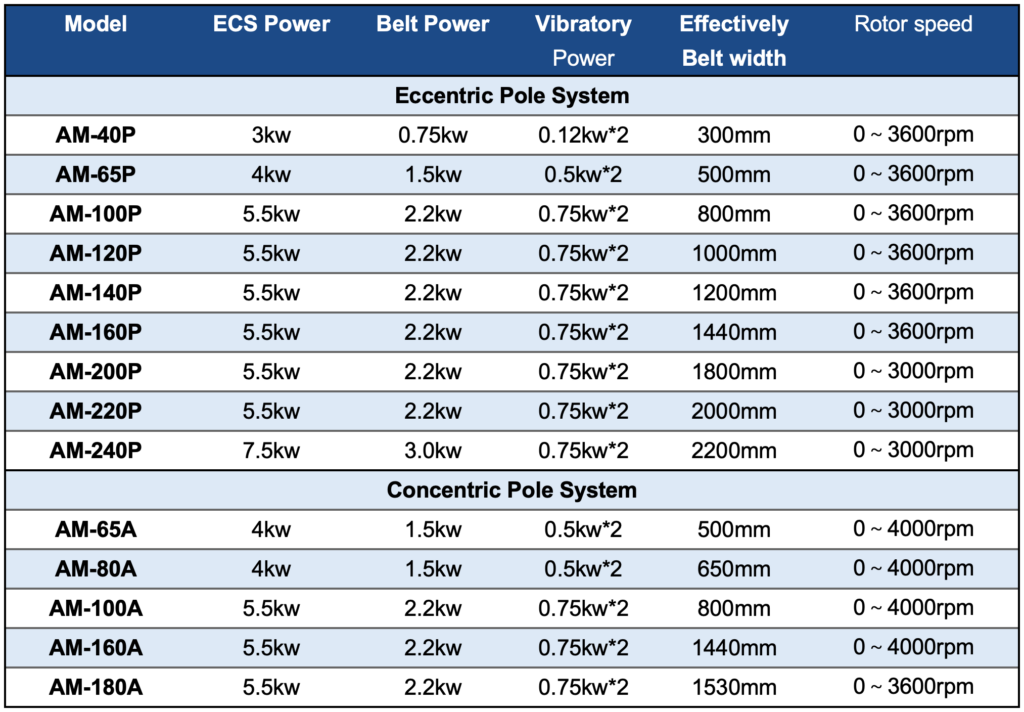

TECHNICAL SPECIFICATIONS

WHY IT’S PERFECT FOR PLASTIC RECYCLING

Precise Metal Removal – Even the smallest non-ferrous metals, as small as 1-2mm, can be effectively separated from plastic materials, ensuring purer plastic output for downstream processing.

Enhanced Plastic Purity – By eliminating contaminants like aluminum and copper, the separator plays a critical role in producing high-quality recycled plastic that meets industry standards.

Designed for High Throughput – With a rotor speed of 3000-4000 rpm and magnetic intensity up to 4500 Gauss, it’s capable of handling large volumes efficiently, making it ideal for high-demand recycling operations.

USER-FRIENDLY DESIGN

Quick Belt Replacement

The unique structure makes replacing the Eddy Current Belt fast and hassle-free, minimizing downtime.

Automatic Alignment

Advanced rollers automatically adjust belt alignment, ensuring uninterrupted operation and reducing maintenance efforts.

Guided Stability

A guiding idler adds extra stability, safeguarding the system when metals pass through, ensuring durability and consistent performance.

WHY CHOOSE US?

With years of expertise and a focus on performance, reliability, and ease of use, our Eddy Current Separator delivers top-notch results. Whether handling small or large volumes, its versatile design and powerful features make it the perfect fit for the plastic recycling.

PROJECTS

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.