The line includes a debaler, belt conveyors, a trommet, two crushers, a friction washer, floating tank, centrigual dryer, hot air dryer, zig-zag separator, and a final storage silo.

This is a trial run of our 2500kg/hr rigid plastics washing plant for a returning customer in Charlotte, USA. We supplied a similar line to this customer in 2022.

This is a trial run of a rigid plastic washing plant for our customer in North Carolina, USA. They are the largest recycling plant in the state!

Explore the capabilities of our Plastic film / turf washing plant in Dalton, GA, designed specifically for the efficient and effective recycling of plastic films.

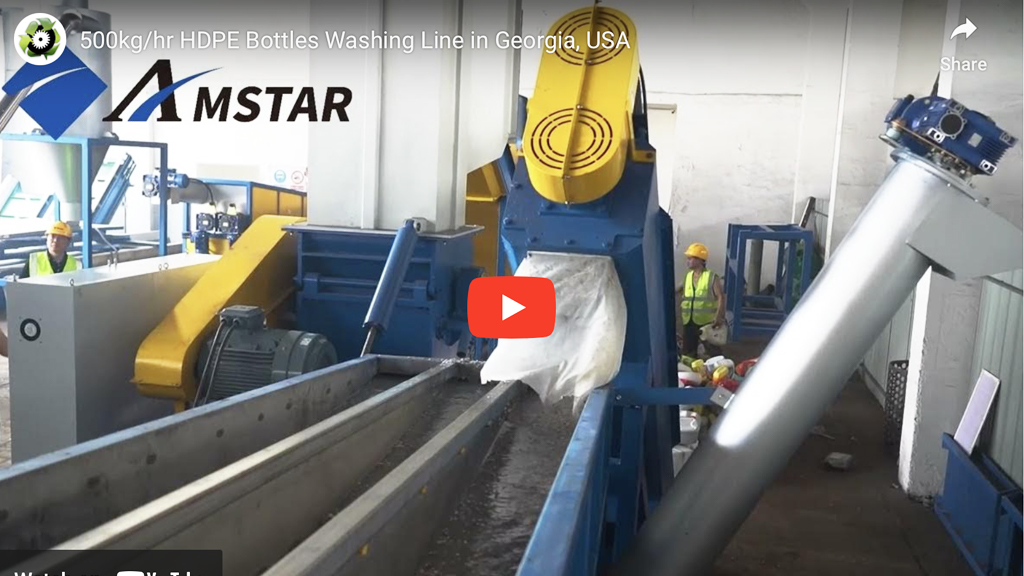

Welcome to our video on the specialized HDPE bottles crushing and washing line designed for our client in Georgia. This plastic recycling system, capable of processing 500 kg per hour, is tailored to handle HDPE bottles efficiently and effectively.

Welcome to our PET Bottle Recycling Line, designed for efficiency and reliability with a capacity of 1 ton per hour. The journey begins with a belt conveyor that transports PET bottles smoothly to the next stage.

Discover the advanced features of our 2000kg/hr HDPE PP Rigid Plastic Crushing and Washing Line, located in Swadlincote, UK.

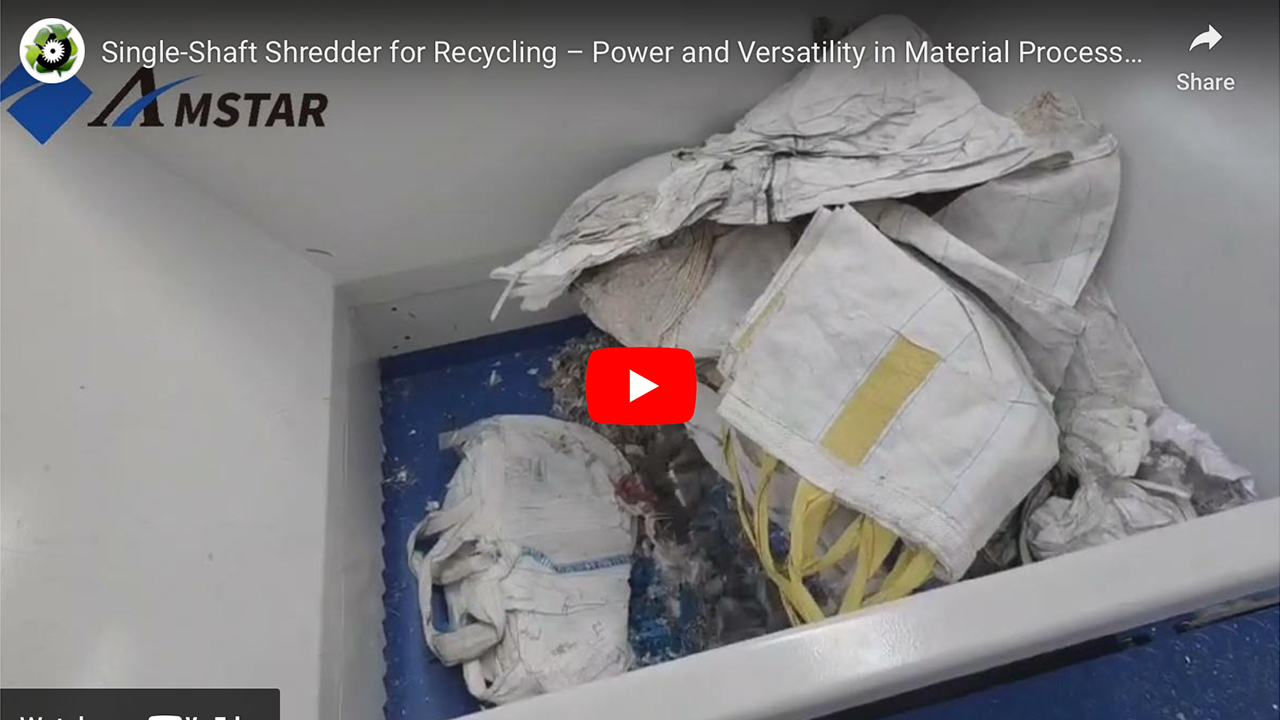

The process begins with shredding, where a single-shaft shredder is used to handle whole bales of PE plastic film with ease. Equipped with a powerful rotor and durable blades, the shredder breaks down bulky materials into uniform strips.

This is a trial run of our PET bottle washing line for a UK customer that been with us for more than 10 years! This 2,000 kg/hr recycling line is the most complex...

Welcome to this video showcasing the power and versatility of our single-shaft shredder. Designed for high-efficiency shredding, this machine can handle a wide range of materials.