This pelletizing system is specially developed for processing PET flakes, especially when the input material is not fully clean.

The line includes a debaler, belt conveyors, a trommet, two crushers, a friction washer, floating tank, centrigual dryer, hot air dryer, zig-zag separator, and a final storage silo.

Looking for durable, high-performance replacement blades for your plastic shredder? We’ve got you covered. We stock a wide range of shredder blades for immediate shipment, including both fixed blades (stationary knives) and rotating blades (rotary knives).

This is a trial run of our 2500kg/hr rigid plastics washing plant for a returning customer in Charlotte, USA. We supplied a similar line to this customer in 2022.

Plastic pipes, made from materials such as HDPE, PE, PVC, and PPR, are widely used across industries, including sanitation, construction, and telecommunications.

This is a trial run of a rigid plastic washing plant for our customer in North Carolina, USA. They are the largest recycling plant in the state!

Explore the capabilities of our Plastic film / turf washing plant in Dalton, GA, designed specifically for the efficient and effective recycling of plastic films.

Among the most common options are single shaft and double shaft shredders, each with distinct advantages suited to different types of materials and operational requirements.

Eddy Current Separators (ECS) are advanced magnetic separation machines designed to remove non-ferrous metals such as aluminum and copper from PET recycling streams.

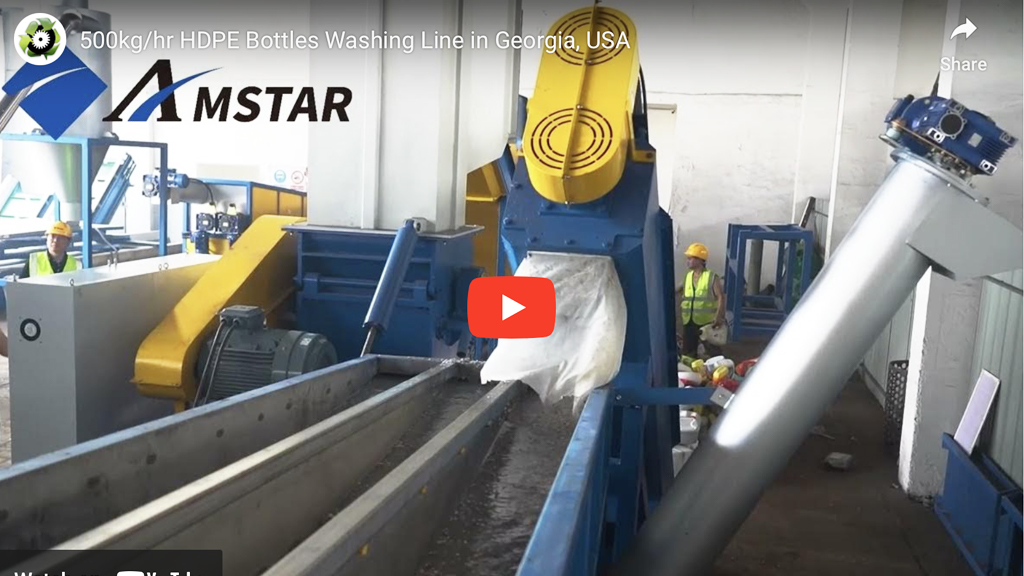

Welcome to our video on the specialized HDPE bottles crushing and washing line designed for our client in Georgia. This plastic recycling system, capable of processing 500 kg per hour, is tailored to handle HDPE bottles efficiently and effectively.