The Roller / Disc Screen is a high-performance, heavy-duty screening solution specifically designed for plastic recycling lines. Featuring multiple rotating shafts equipped with cast-steel or coated discs, this equipment excels at precise size-based separation, making it a vital pre-sorting unit for modern PET, HDPE, PP, and mixed plastic recycling systems.

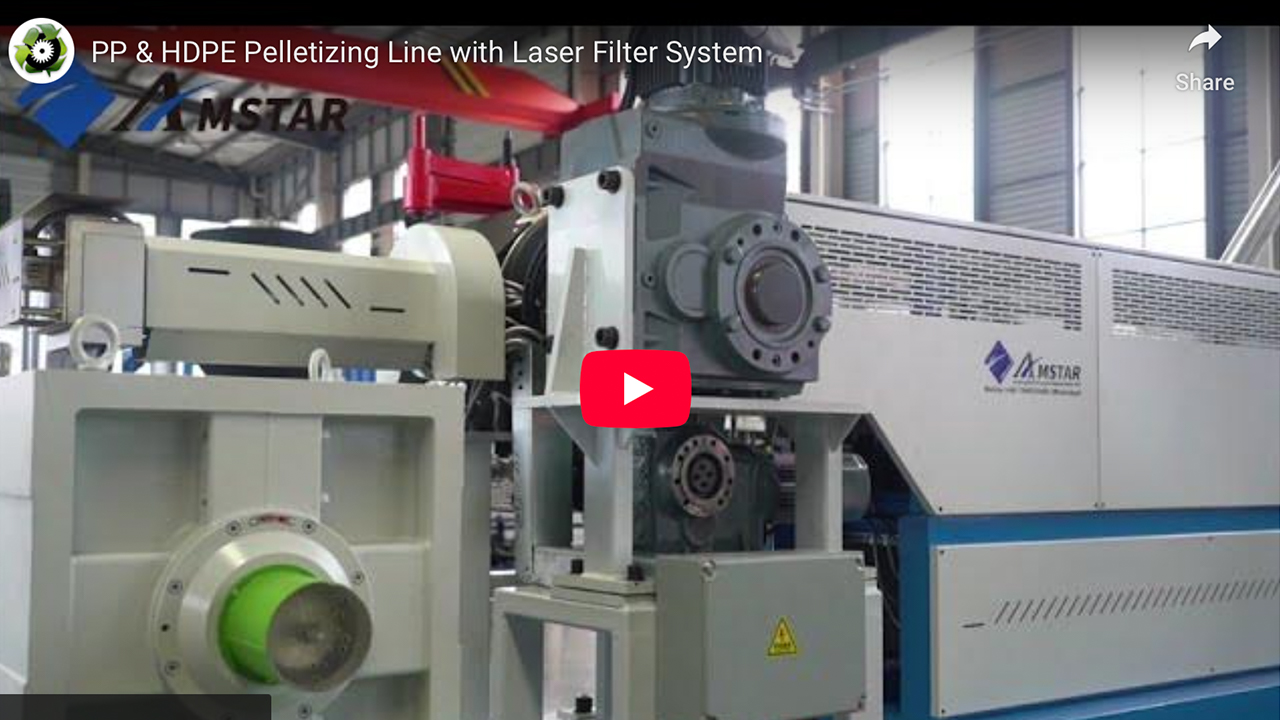

Featuring our Laser Filter Automatic Screen Changing and Slag Discharge System, this line delivers uniform, high-quality pellets even from highly contaminated input materials.

This is a trial run of our 300 kg/hr PP PE Film pelletizing line for a customer in Auburn, USA that processes clean PP PE plastic films.

This is a trial run of our BOPP film pelletizing line for a customer in Halifax, United Kingdom. This system comes equipped with our well designed piston-type screen changer and many other new technologies

The PET Bottles Crushing and Washing Line in Perth, Australia, is engineered for recovering PET bottles at a capacity of 3 tons per hour.

Today we’re taking a closer look at a complete PP woven bag shredding and pelletizing line with a capacity of 500 kilograms per hour.

Amstar introduces a reliable, space-saving solution for recycling bulky EPS materials with our EPS Hot Melting Machinery series. These machines transform foam waste into dense ingots, reducing volume by up to 90%, easing storage and transportation, and enabling eco-friendly reuse.

The Sludge Dewatering Machine, also known as the Screw Press Sludge Dewatering Machine, is an advanced solid-liquid separation equipment widely used in municipal wastewater treatment and various industrial applications.

We’re excited to showcase our twin shaft plastic shredder, a powerhouse machine designed for demanding plastic waste reduction tasks.

Purpose-built for recycling facilities and plastic processing operations, this machine is ideal for handling a wide range of plastic waste, including films, bags, pipes, and solid chunks.