In the plastic recycling industry, shredders play a pivotal role in processing waste materials. Among the most common options are single shaft and double shaft shredders, each with distinct advantages suited to different types of materials and operational requirements. This article will provide a detailed comparison of these two types of shredders, highlighting their features, advantages, and specific applications to guide businesses in choosing the most appropriate shredder for their needs.

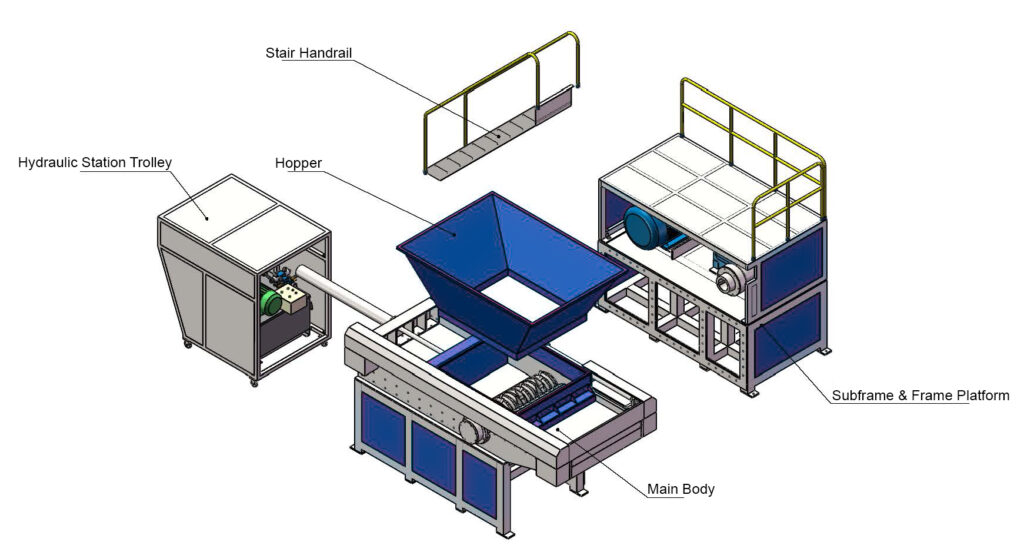

See below example of Single-Shaft Shredder:

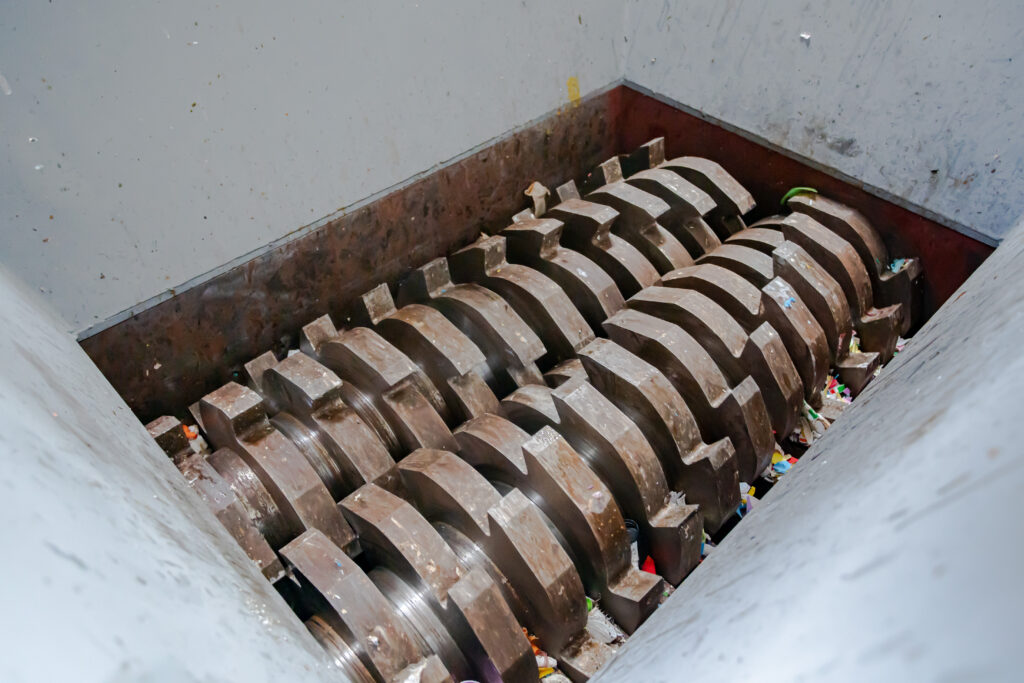

See below example of Double-Shaft Shredder:

1. Structure and Working Principle

Single Shaft Shredder

A single shaft shredder consists of a high speed rotating main shaft equipped with multiple cutting blades. These blades shred the material against a stationary counter knife. The output size is controlled by the gap between the blades and the counter knife, as well as the screen mesh beneath the blades.

- Uses a spiral type rotating knife and saw tooth fixed knife for efficient cutting.

- Equipped with a movable hopper to prevent material bridging and optimize feed flow.

- Features a coupling connection to extend gearbox lifespan.

- Suitable for plastic film, fiber, purges, packed paper, wood, and general plastic waste.

Double Shaft Shredder

A double shaft shredder has two shafts with counter rotating blades. These blades grip and tear the material through shear force and torque, making it ideal for large, tough, and rigid materials.

Uses two interlocking shafts to provide a high torque cutting motion.

No screen mesh, allowing direct discharge of shredded material.

Designed for industrial and bulky waste, including plastic pipes, tires, drums, e waste, and hard plastics.

Provides better handling of mixed materials, making it widely used in large scale recycling.

2. Performance Comparison

| Feature | Single Shaft Shredder | Double Shaft Shredder |

| Shredding Capacity | Ideal for shredding soft materials like films, bags, and bottles | Better for shredding thick, tough materials like pipes, drums, and bulky waste |

| Output Size | Larger output size, lower uniformity | Smaller output size, higher uniformity |

| Processing Efficiency | Relatively lower processing efficiency | Relatively higher processing efficiency |

| Energy Consumption | Lower energy consumption | Higher energy consumption |

| Maintenance Cost | Simpler structure, lower maintenance cost | More complex structure, higher maintenance cost |

3. Advantages and Features: Single Shaft vs. Double Shaft Shredder

A. Shredder Main Shaft

- Single Shaft: Uses a solid forged round shaft, heat treated for durability. The screw locked blades ensure uniform axial force distribution for stable long term operation.

- Double Shaft: Features two high strength steel shafts, designed for low speed, high torque operation, minimizing blade wear when processing rigid materials.

B. Coupling and Drive System

- Single Shaft: Includes a precision engineered coupler with 12 pin torque transmission, extending gearbox life by buffering mechanical forces.

- Double Shaft: Uses a dual motor and planetary gear reducer for higher torque and reliable continuous operation.

4. Performance and Application Suitability

| Application | Single Shaft Shredder | Double Shaft Shredder |

| Plastic Film & Fibers | ✅ Yes | ❌ No |

| Soft Plastics (PE, PP, PVC, PET) | ✅ Yes | ✅ Yes |

| Hard Plastics (HDPE, PC, ABS) | ⚠️ Limited | ✅ Yes |

| Plastic Pipes & Drums | ✅ Yes | ✅ Yes |

| E Waste & Electrical Components | ⚠️ Limited | ✅ Yes |

| Tires & Rubber Waste | ❌ No | ✅ Yes |

| Wood & Paper Waste | ✅ Yes | ✅ Yes |

| General Household Waste | ⚠️ Limited | ✅ Yes |

| Bulky Industrial Waste | ❌ No | ✅ Yes |

| Silicone | ✅ Yes | ✅ Yes |

✅ Yes = Highly Recommended

⚠️ Limited = Can Process, But Not Optimal

❌ No = Not Suitable

5. Conclusion: Which Shredder Should You Choose?

Choose a Single Shaft Shredder if:- You primarily process soft plastics, film, fiber, paper, and wood.

- You need fine, uniform output with controlled size.

- You require higher processing speed for lightweight materials.

- You want lower maintenance costs and simpler operation.

- You deal with large, hard plastics, bulky waste, pipes, or tires.

- You need a high torque machine for industrial waste.

- You process mixed materials and require more versatility.

- You need longer lasting blades and lower wear.

Amstar Plastic Shredders

Amstar offers both single shaft and double shaft shredders, designed to meet the needs of various industries.- Our Single Shaft Shredder is ideal for soft plastics, films, fiber, and small plastic objects, offering precise control over output size.

- Our Double Shaft Shredder is built for bulky waste, industrial plastics, and tougher materials, ensuring high torque, efficient shredding.

Amstar’s Project Cases

Watch the project demonstration of our Single Shaft Plastic Shredder for PP PE Plastic films in action Click here to view the video

Watch the video demonstration of our Single Shaft Plastic Shredder in action Click here to view the video

Watch the video demonstration of our Double Shaft Plastic Shredder for Recycling Children’s safety seats in action Click here to view the video

For expert advice or more information about Amstar’s PET recycling solutions, contact our team today. Together, we can create a cleaner, more sustainable future.