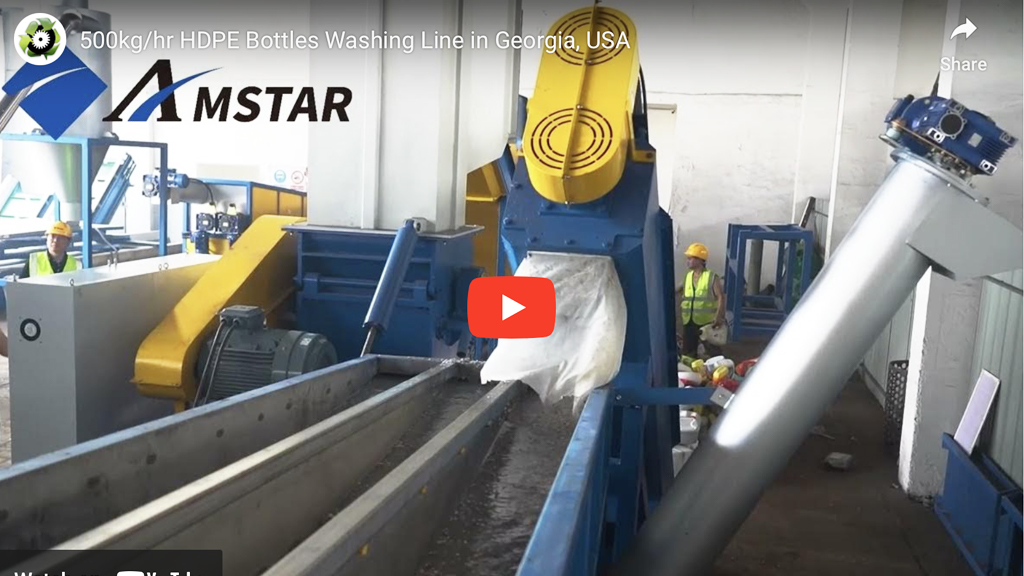

Welcome to our video on the specialized HDPE bottles crushing and washing line designed for our client in Georgia. This plastic recycling system, capable of processing 500 kg per hour, is tailored to handle HDPE bottles efficiently and effectively.

The journey begins with the Belt Conveyor, which evenly feeds the HDPE bottles into the system.Next, the bottles meet the Crusher, where they are broken down into smaller pieces.

After crushing, the material moves via a Screw Conveyor to the Friction Screw, where initial cleaning and separation of minor impurities occur.

This leads us to the centerpiece of our cleaning process, the Triple Row Floating Tank. Here, floating debris like labels and caps are separated from the denser plastic fragments.

Following this separation, the plastics go through another Floating Tank to ensure thorough cleaning.

Then through Screw Conveyor, the Centrifugal Dryer, the Hot Air Dryer,and Label Separator ,preparing the plastics for the final stages of recycling.

Finally, the cleaned and dried plastic flakes are conveyed to the Finished Product Silo, where they are stored before being processed into new products.

Please feel free to contact us if you are interested in this system so we can make a proposal for you.

INQUIRIES

To learn more about this product, please send us a message using the form below: